About AFOSOL

Established in 2016 as a joint venture between the renowned Autoprint Machinery Manufacturers (Autoprint) Coimbatore, Swiss pressroom chemistry experts, and German application specialists, AFOSOL aims to supply demanding printers with highest quality consumables. All products rest on sophisticated formulations developed and optimized in close cooperation with leading European printing machinery manufacturers, proven over decades.

Manufactured in Coimbatore, we sell our products all over India along with exporting to adjacent countries. Based on strong partners, valuable customer feedback and tight cooperation with leading international press manufacturer, AFOSOL is consistently at the leading edge of development.

AFOSOL has developed a series of highest quality maintenance products covering the full range from specialized to more generalist applications, caring about production tools by following maintenance cycles is a precondition for industrial production. Keeping up the value of invested resources.

Why is Press Chemistry Important in Press?

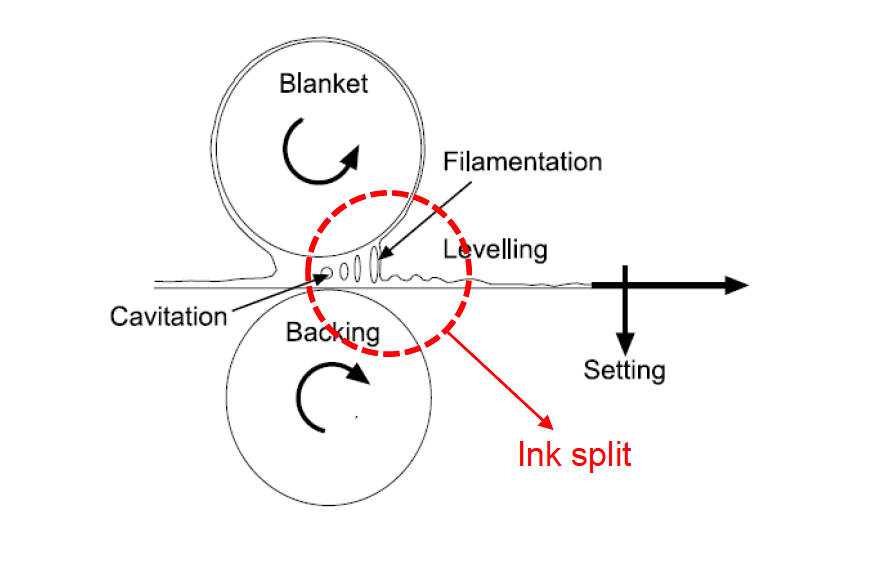

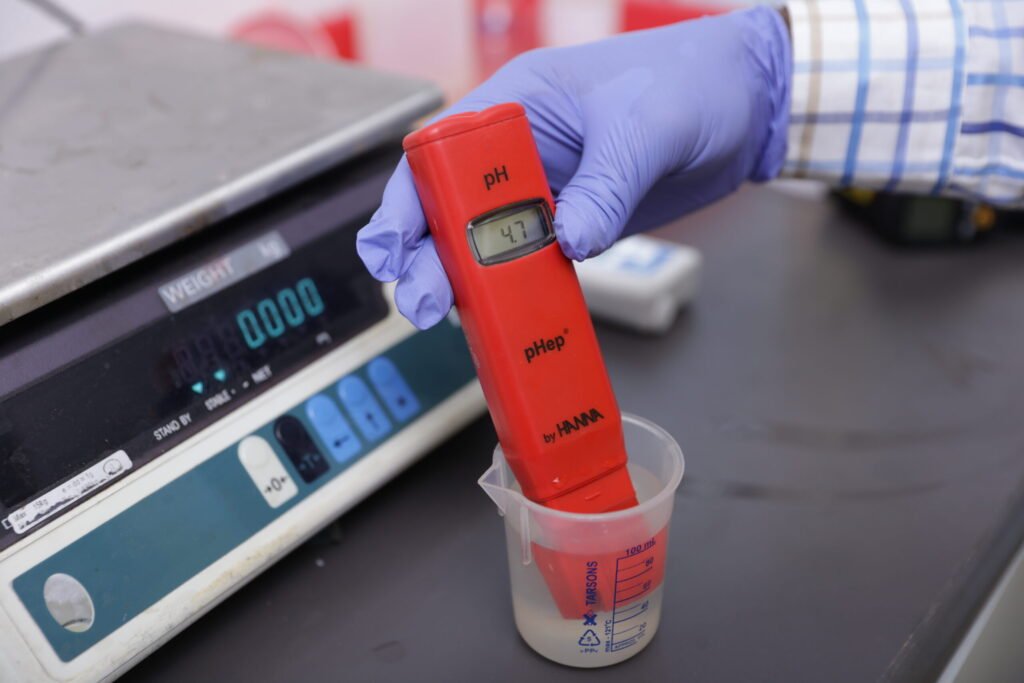

A high-quality printing product is represented by highest print contrast, balanced gray shades, sharp and detailed image definition with color consistency from sheet to sheet. To achieve this, we require a stable press with homogenous dampening distribution from head to tail of the plate and an excellent ink split behavior. Profit margin in printing is a direct result of cost of production, material required, turnaround time (the faster the better) and the selling price of the finished printed product. One important factor in achieving high quality with profit margins is “the chemical cocktail” in the press or in other words the applied “consumables”.

After having done many “press adjustment” training to printers we found out that this was a very critical factor for operators which need to be understood and controlled. Therefore, together with leading partners we developed a series of press chemistry to get the “split of ink” ideally set.The result: A minimum of water or dampening to get the right dot gain in relation to the best ink lay-down or ink density.

Why?

Because the lesser the water in the interaction:

- The better lay down of ink and color saturation,

- The lesser time required to dry the sheet,

- The lesser time required to print the backside or to finish the product,

- The lesser powder consumption, and

- No color variation hence highly consistent print run.

By considering this, it becomes easier to reach and keep the International ISO standard for offset (ISO 12647-2)